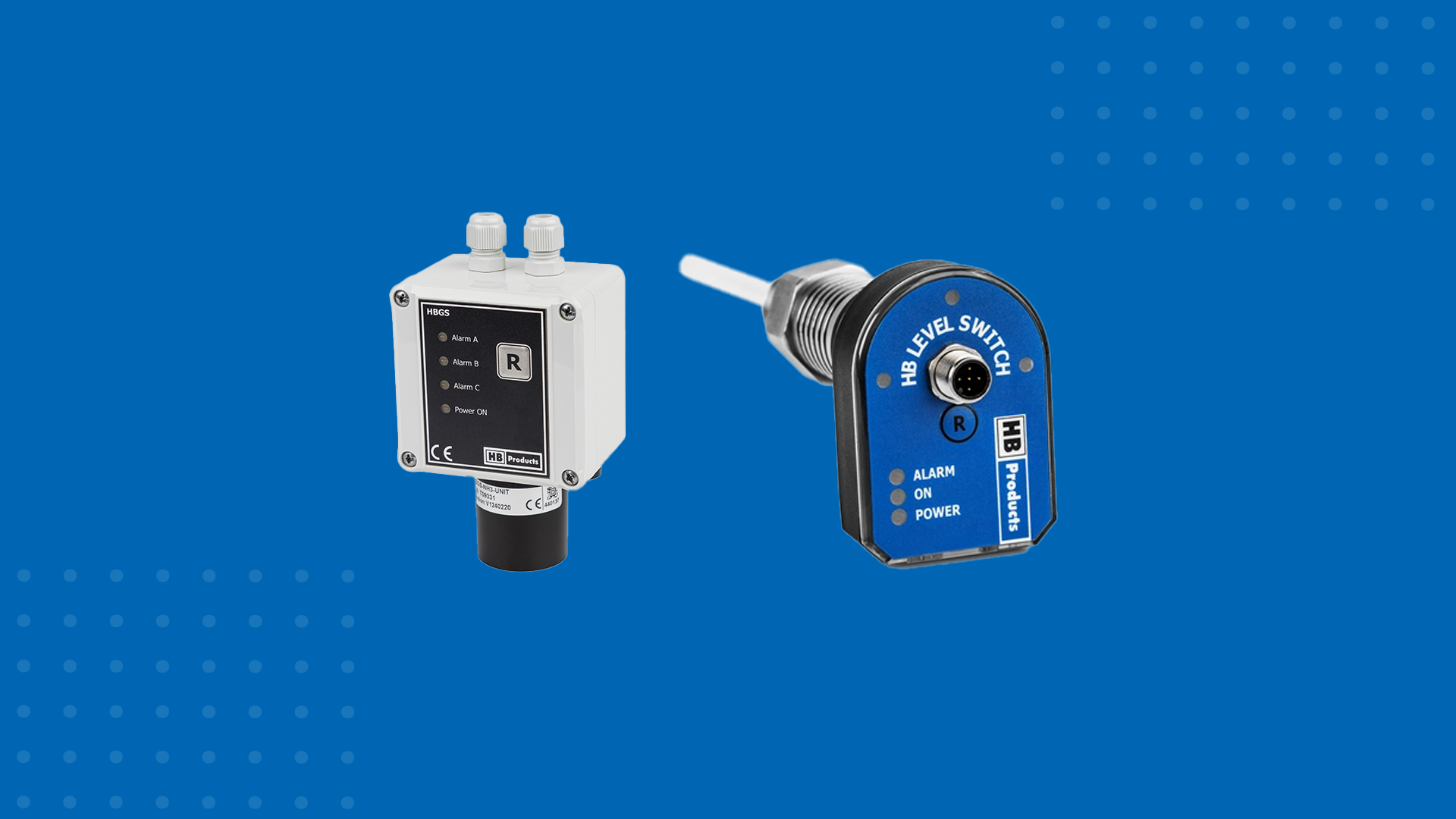

Control and Detect Liquid Levels With Our Wide Variety of Innovative Switches

With our Liquid Level Switches, you avoid the challenge of moving elements in mechanical switches, which get worn down and ultimately fail. All our Liquid Level Switches utilize capacitive measuring and are designed with a smart split design, ensuring easy maintenance and built to withstand challenging conditions like low and high temperatures, high pressures, and aggressive fluids.

Our Level Switches Are Designed for the Industry

Efficient and quick installation and diagnostics

Reliable performance in -60°C to 145°C (-76°F to 293°F)

Flexible power supply with both AC and DC power

Suitable for various liquids like ammonia, CO2, and butane

Easy plug-and-play configuration with HB Tool

See How Our Liquid Level Switches Work

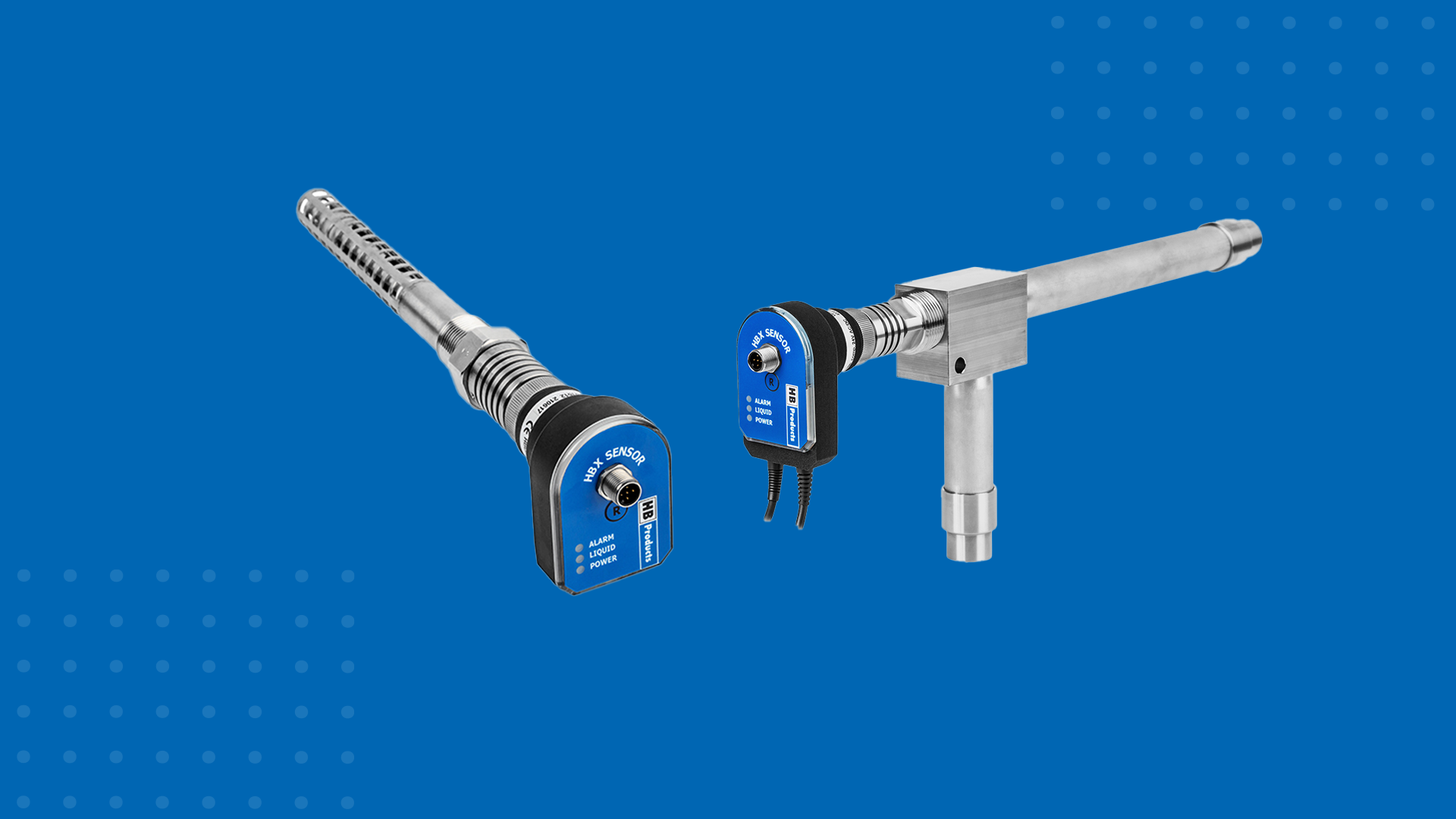

Achieve a Simple Approach to Automatic Oil Return with Our Oil Management Program

Our product range includes sensors designed for measuring and transmitting oil levels.

The Oil Ejector combines an oil switch with an ejector, providing a simple and reliable solution for systems with ammonia or CO2, and eliminating the need for an expensive oil pot.

As it reuses some of the refrigerant in the system, it helps to optimize the refrigerant cycle and reduce the load on the compressor, which in turn reduces energy consumption.

Our Sensors in ammonia systems

Our Switches in CO2 systems

Liquid Level Switch Selection Guide

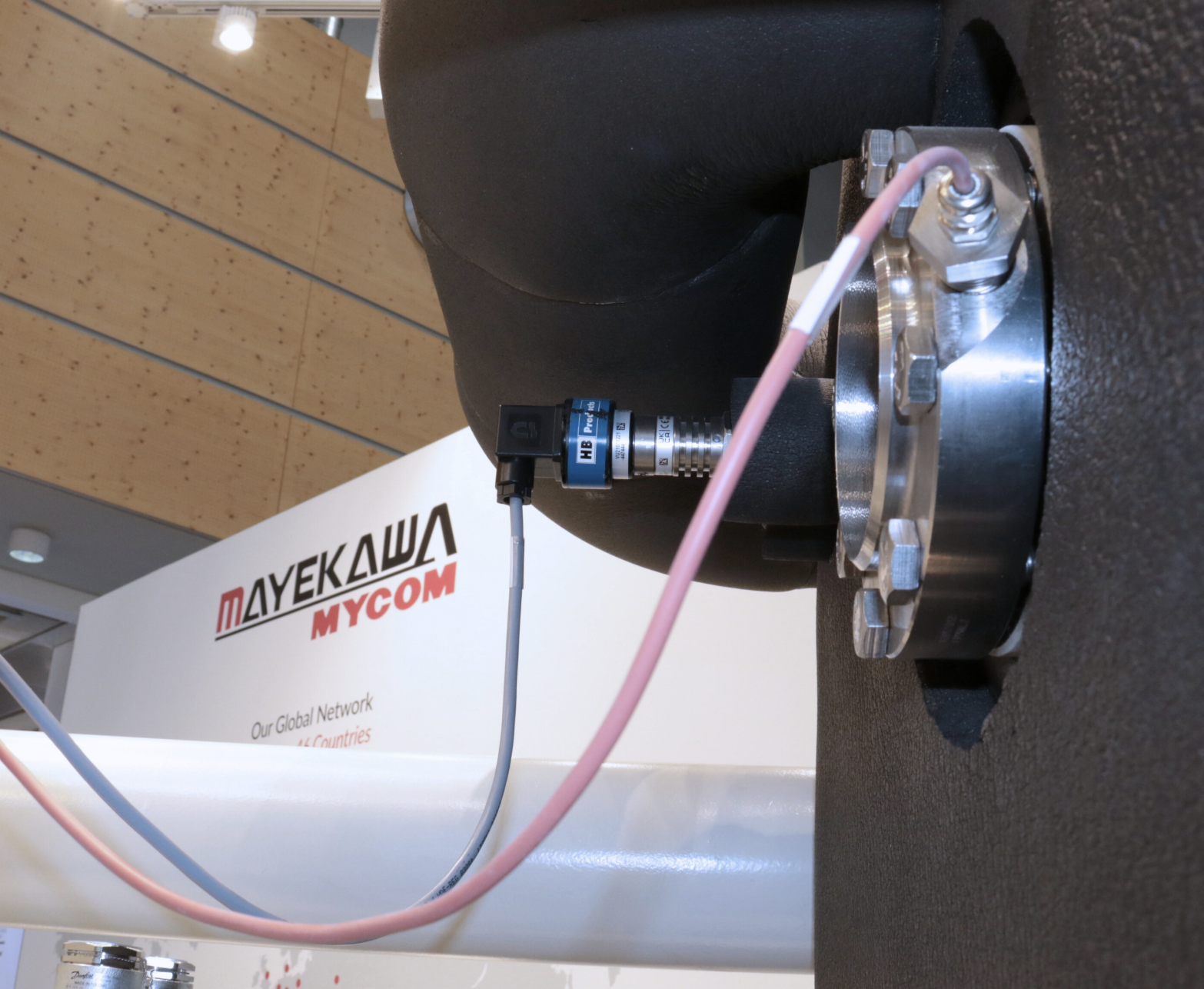

Mayekawa Nordic Found a Reliable and Robust Solution From HB Products

Mayekawa Nordic was in need of a new and durable oil and refrigerant management solution for their ammonia (NH3) chillers — they found it with our HBSR switch.

The switch is designed for industrial ammonia systems and is capable of withstanding pressures of up to 100 bar, while the split design proved to be a valuable feature.

“The separation between the mechanical and electrical part makes servicing easier. No need to drain the refrigerant charge to change a defective electronics component,”

Claus Ødegaard, Sales Manager at Mayekawa Nordic.

You can read the entire case study below.