Precise Liquid Level Sensors for Both Natural and Synthetic Refrigerants

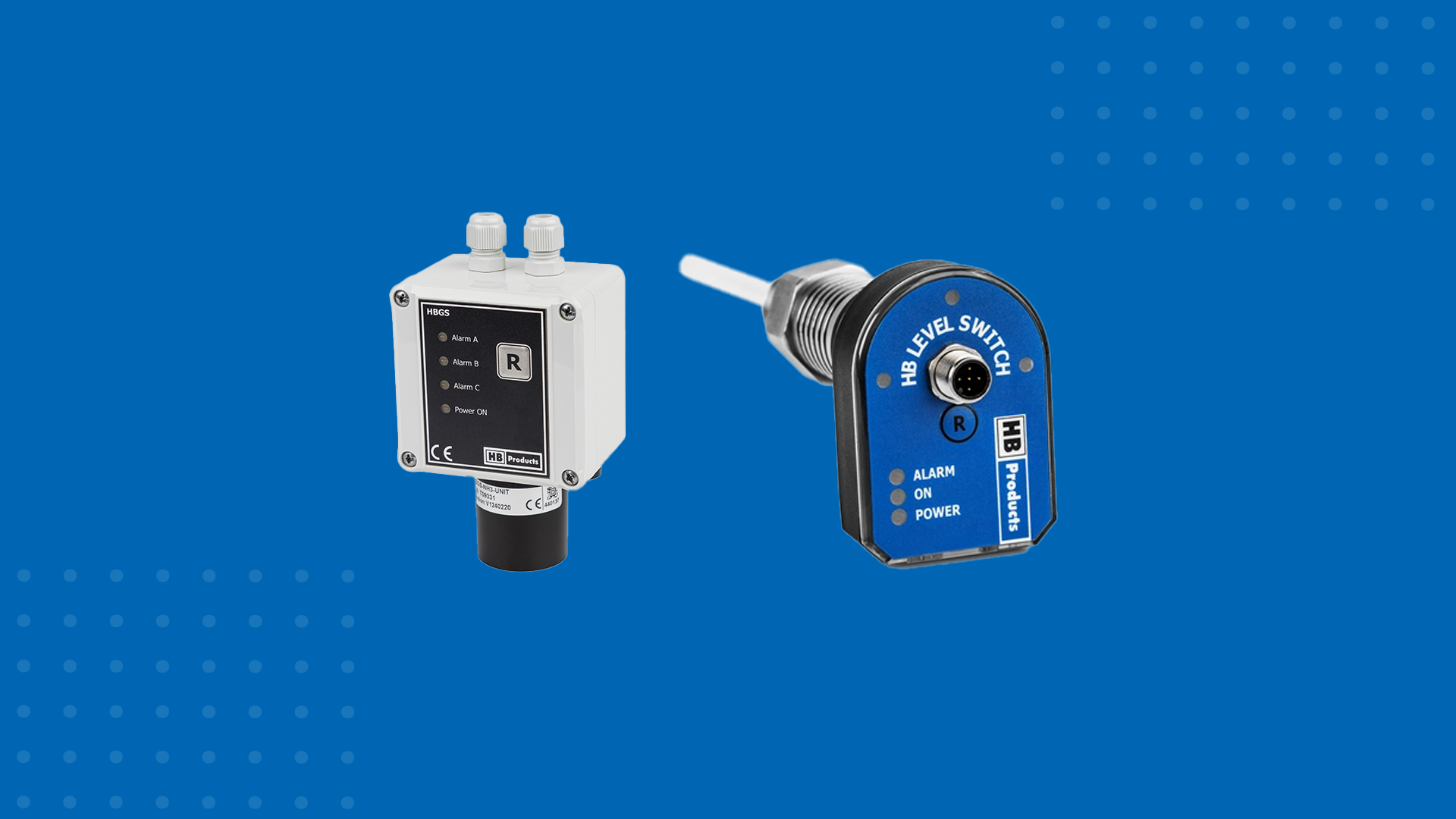

Are you looking to ensure a high-quality solution for every type of environment? Take a closer look at our Liquid Level Sensors. With a smart split design, our Liquid Level Sensors provide a durable, easily maintained, and cost-effective solution for accurate monitoring.

Our Level Sensors Are Designed for the Industry

Efficient and quick installation and diagnostics

Reliable performance in -60°C to 80°C (-76°F to 176°F)

Adjustable length of the mechanical part

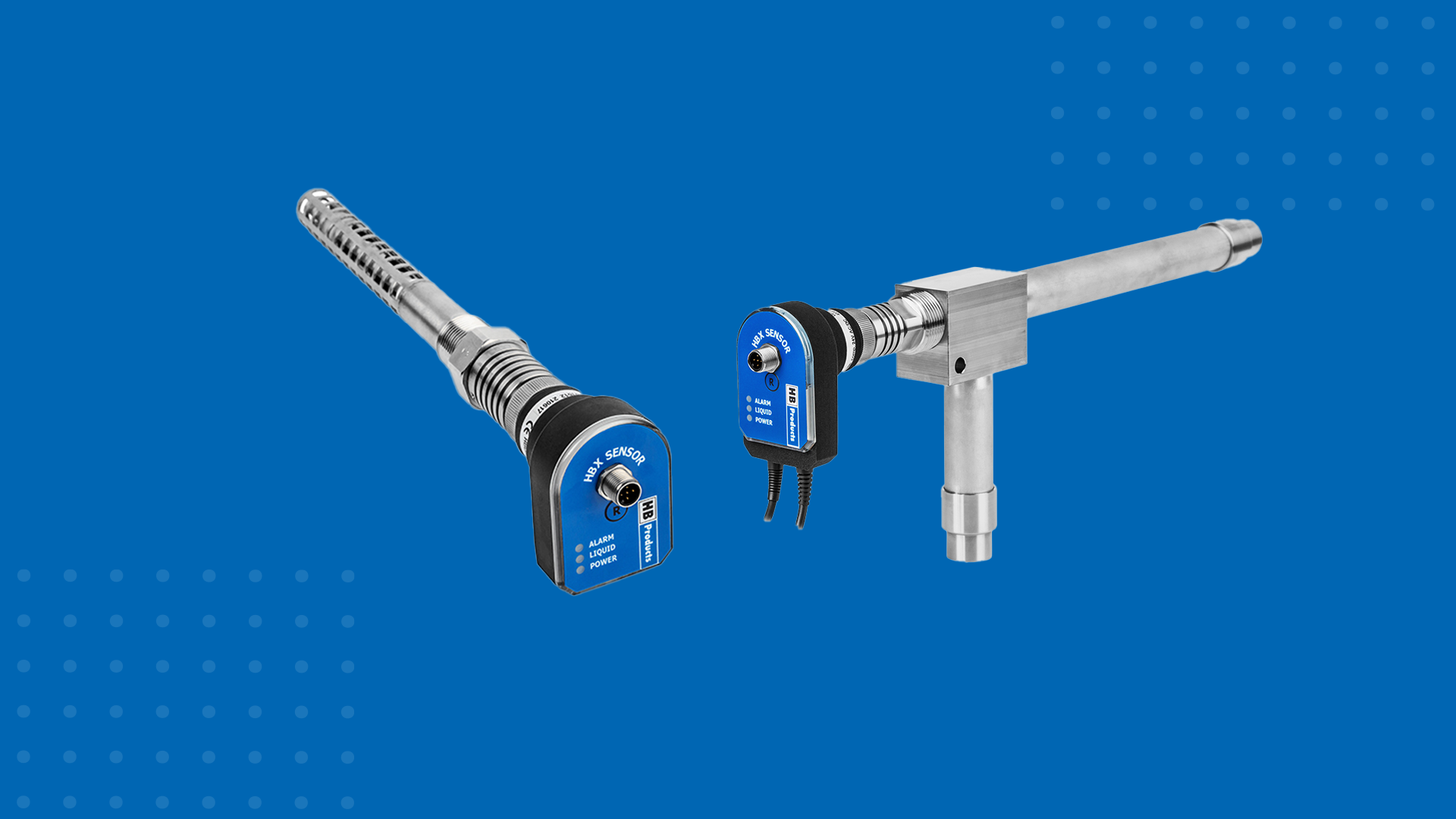

Suitable for various liquids like ammonia, CO2, and butane

Easy plug-and-play configuration with HB Tool

See How Our Liquid Level Sensors Work

Achieve a Simple Approach to Automatic Oil Return With Our Oil Management Program

Our product range includes sensors designed for measuring and transmitting oil levels.

The Oil Ejector combines an oil switch with an ejector, providing a simple and reliable solution for systems with ammonia or CO2, and eliminating the need for an expensive oil pot.

As it reuses some of the refrigerant in the system, it helps to optimize the refrigerant cycle and reduce the load on the compressor, which in turn reduces energy consumption.

Our Sensors in ammonia systems

Our Sensors in CO2 systems

Liquid Level Sensor HBLT-Wire

Liquid Level Sensor Selection Guide

Efficient Installation and a Durable Sensor for Exodraft Energy With HB Products

Exodraft Energy was in need of a highly durable Liquid Level Sensor for its ammonia containers. It was paramount that the sensors were capable of handling both cold and warm temperatures up to 70°C (158°F) without becoming unreliable.

The choice fell on our HB Products HBLT-A3 Liquid Level Sensor, which was integrated into the operation without incident and with great results.

You can read the entire case story and learn more about the specifications of the HBLT-A3 Liquid Level Sensor below.