Optimize Your Defrost Cycles with Our Defrost Sensor

By measuring frost accumulation on the surface, our Defrost Sensor initiates defrost cycles only when necessary. This prevents excessive buildup while saving time, money, and energy in the process.

Learn more about the Defrost Sensor by clicking the link below.

Measure and Maintain Ice Thickness with Our Ice Bank Sensor

Our Ice Bank Sensor is designed to provide greater control over your refrigeration system by maintaining optimal ice thickness and utilizing off-peak hours for a more cost-effective solution.

Learn more about the Ice Bank Sensor by clicking the link below.

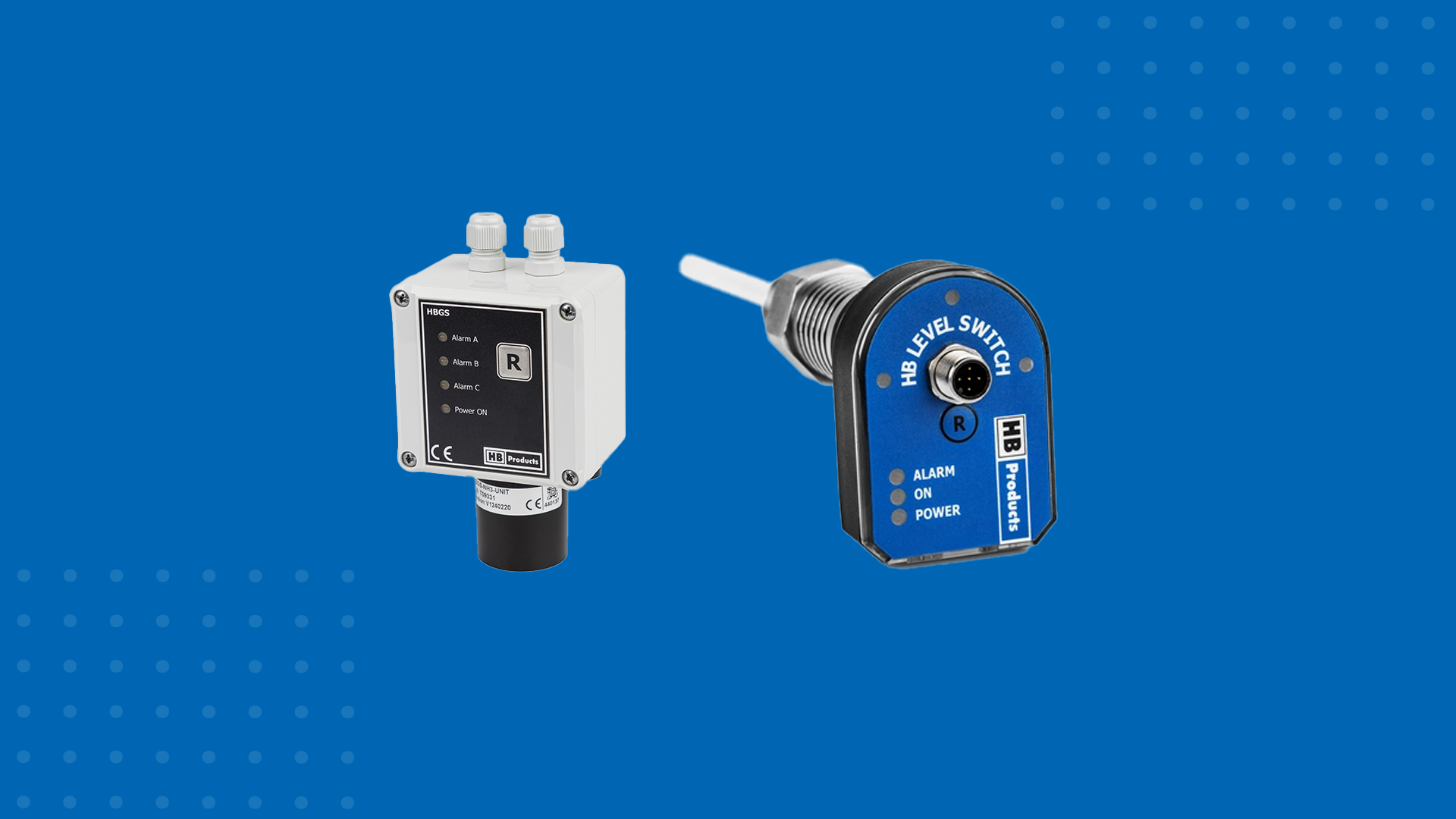

Avoid Excessive Defrost Cycles Without Compromising on Performance and Cooling Capacity

The Defrost Sensor can be installed on both new and existing systems and has shown a reduction in the number of defrost cycles, which typically accumulates to a 20-40% savings in energy costs.

Reduce defrost cycles by up to 50-70%

Based on the capacitive measuring principle

Easy installation without system shutdown

Options to choose between control modes for convenient control

Available in 4 versions with wire lengths ranging from 10 to 30 meters

Accurate configuration with HB Tool

Learn How the Defrost Sensor Works

How to Reduce the Energy-Consumption and Save Money in Your Cold Storage Facility

Would you like to learn more about the benefits of installing our Defrost Sensor on your new or existing evaporators? Download our brochure, where you can find additional information on how the Defrost Sensor works and the installation process.

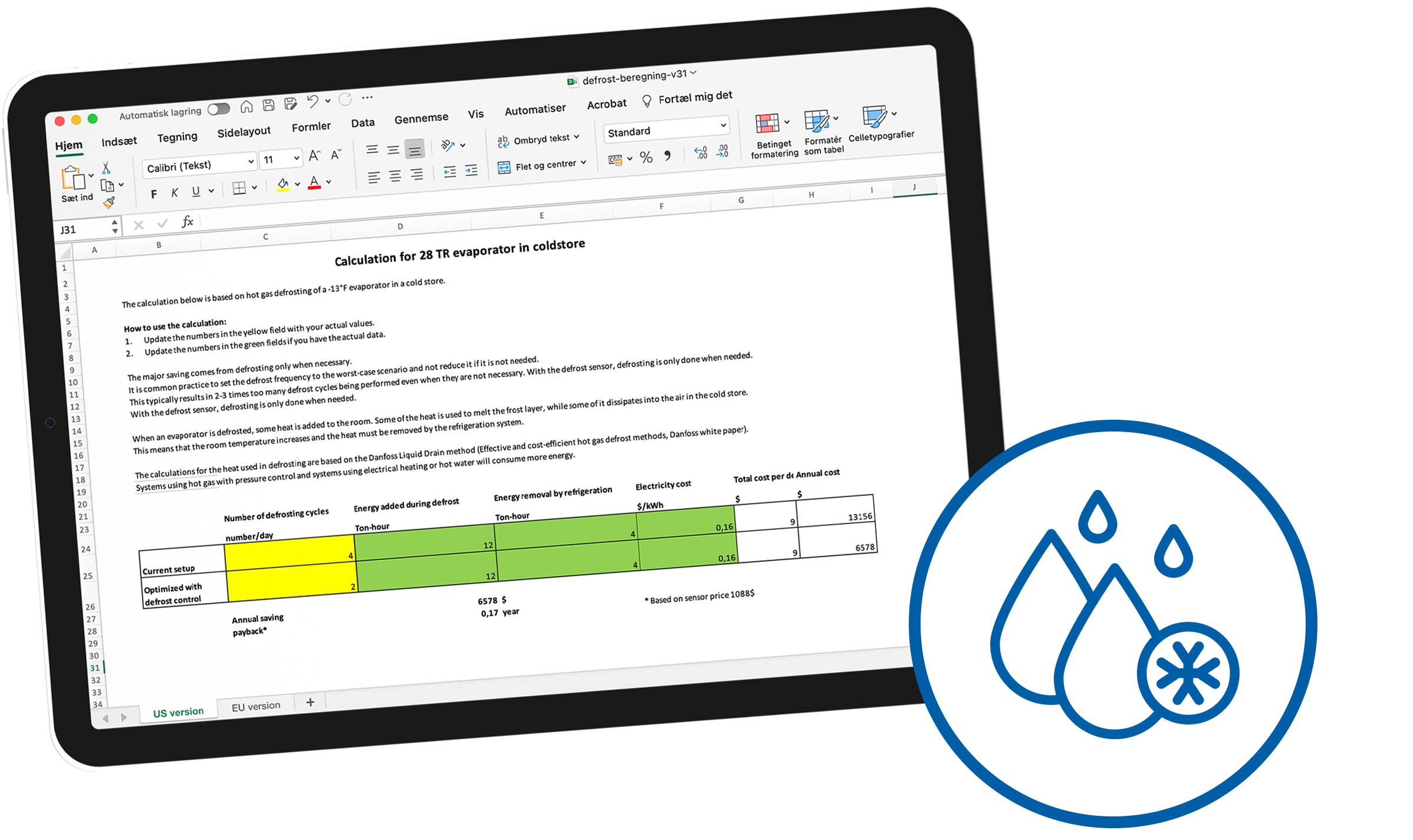

What Is Your Potential Savings by Optimizing Defrosting?

Our Defrost Sensors ensure automatic defrosting based on the capacitive measuring principle, thereby eliminating excessive defrost cycles.

You can calculate your potential savings with our calculator. It is based on the conservative estimation of a 50% reduction, while the heat calculation is based on the Danfoss Liquid Drain method.

Systems using hot gas with pressure control and systems using electrical heating or hot water will consume more energy.

AB-Catering Eliminated Issues With Condensation and Continual Adjustments

For AB-Catering, their defrost cycles had caused serious issues for years, as they needed to adjust the cycles regularly, especially every time spring and fall rolled around.

In addition, they were having problems with condensation that dripped down on the conveyor belt and then froze to ice.

The solution to their problems was the Defrost Sensors from HB Products. Read the entire case study if you are curious about the solution and collaboration.

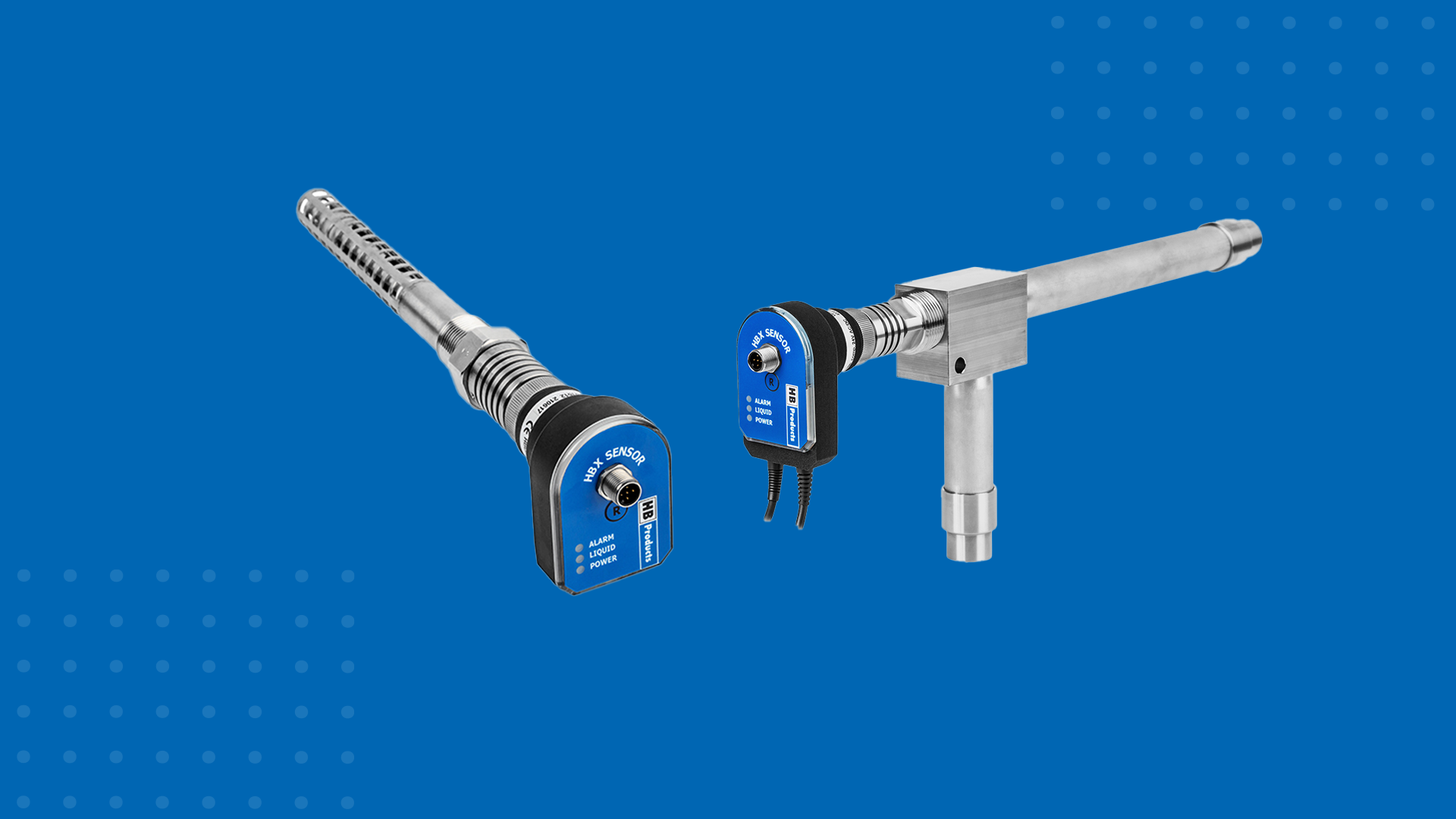

Store Ice During Off-Peak Hours with Our Ice Bank Sensor

Our Ice Bank Sensor is designed to optimize ice storage management in industrial and commercial refrigeration systems.

Using the capacitive measuring principle, the sensor accurately monitors ice build-up, enabling efficient ice storage during off-peak hours. This not only reduces energy consumption but also enhances system reliability by preventing excessive ice formation.

Watch the Ice Bank Sensor in action through the animation.