Energy-Saving Vapor Quality Sensors Suitable for All Refrigerants

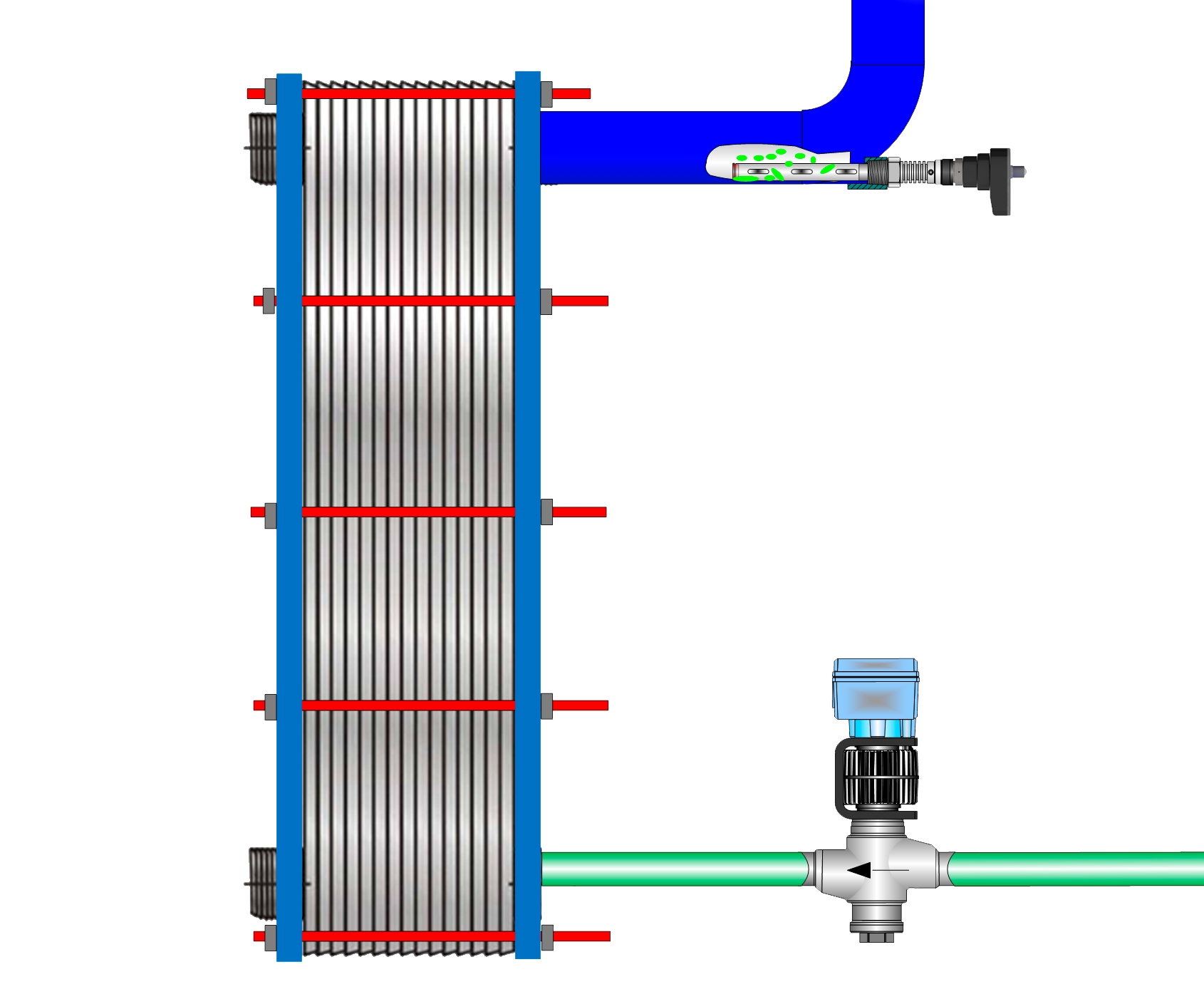

Our Vapor Quality Sensor is designed to measure the liquid content in the evaporator’s output and works in both liquid overfeed and DX systems. The Vapor Quality Sensor provides instant measurement and feedback to improve efficiency, ensure more consistent performance, and optimize energy-consumption. We have documented savings of up to 20% during full load and 50% during part load for a DX ammonia system.

Control the Liquid Flow and Improve Operations With Our Vapor Quality Sensors

Energy-savings of at least 20%

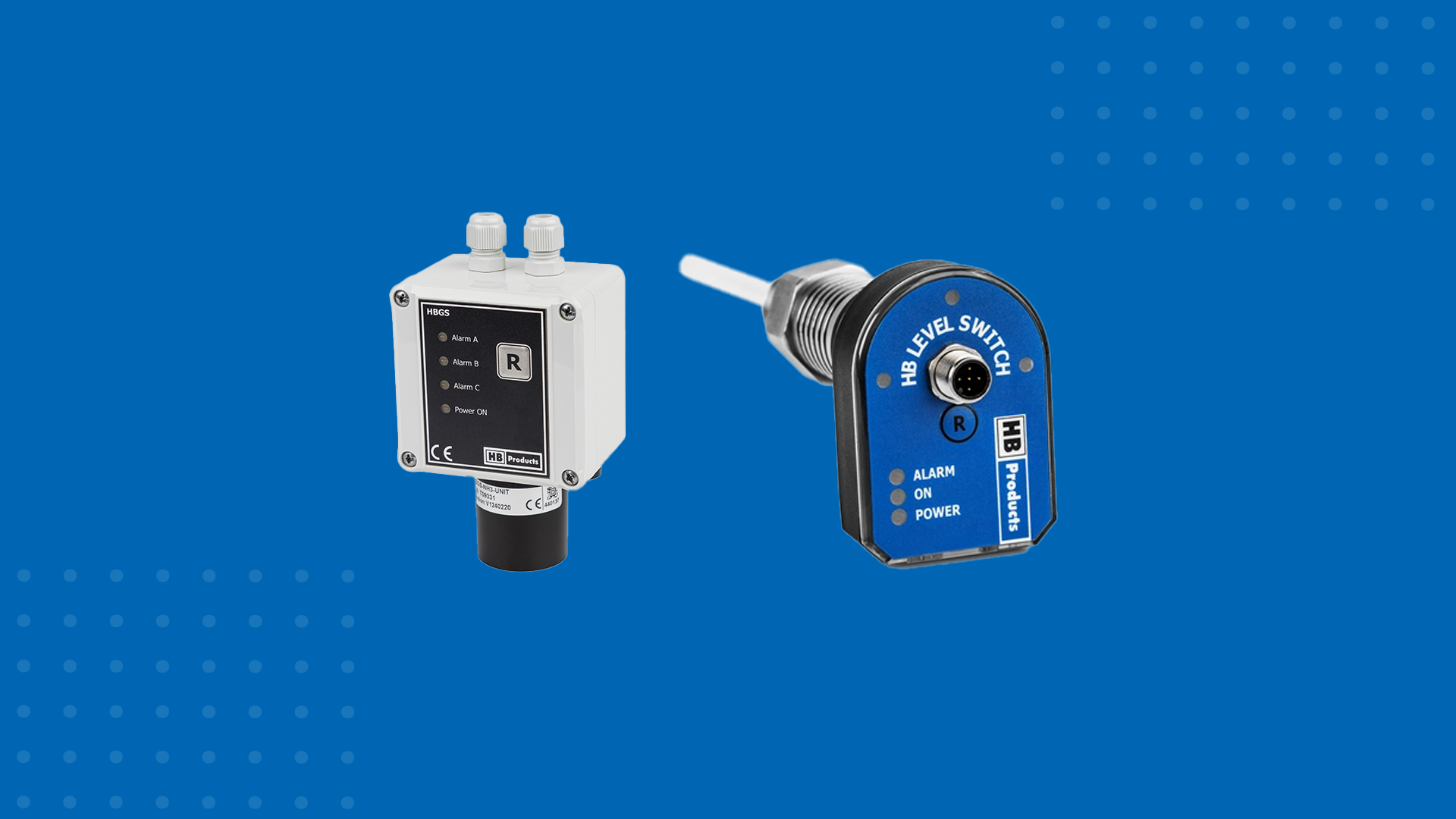

Easy installation with split design

Suitable for all common liquids

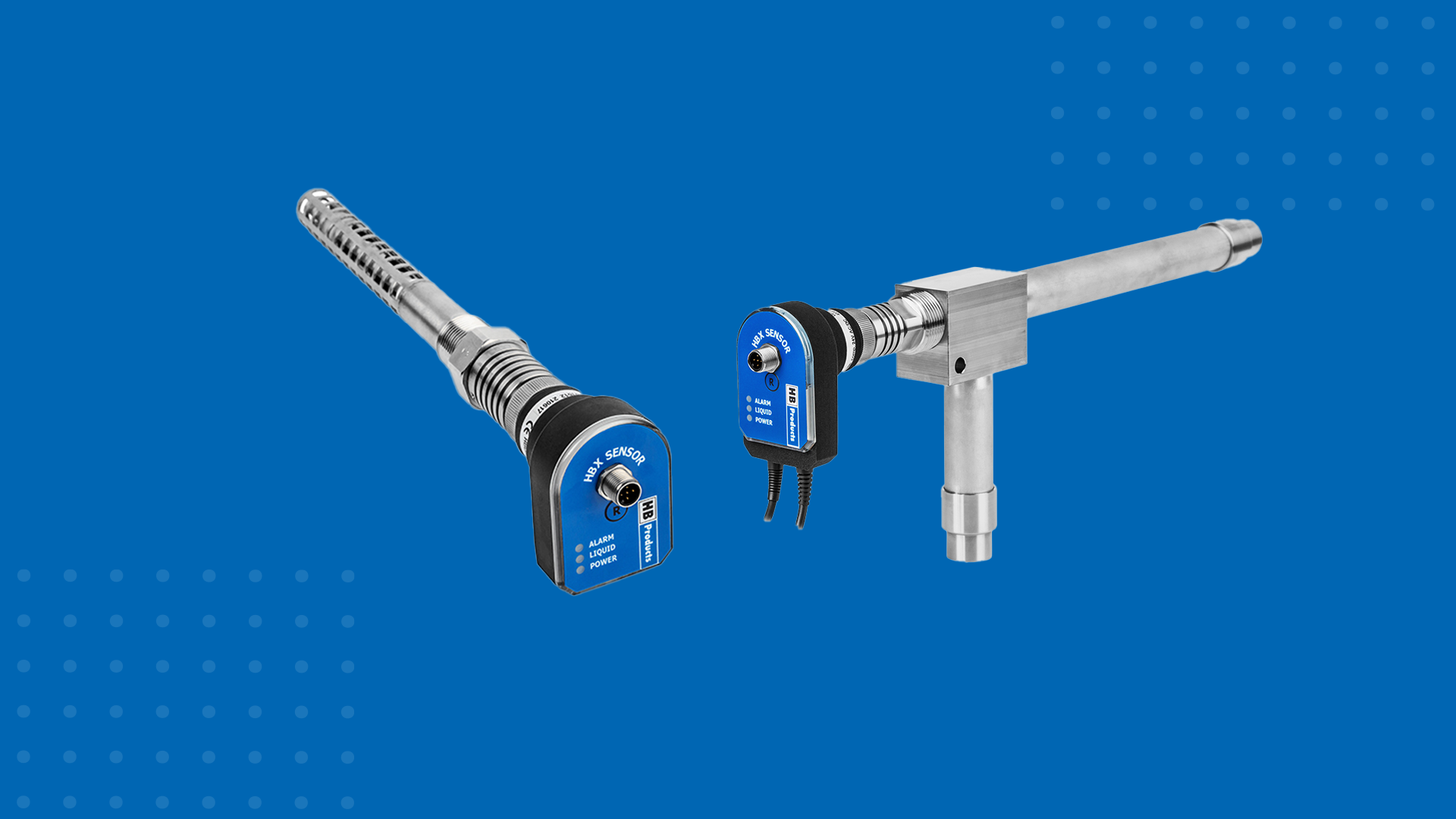

Flexible installation on both horizontal and vertical pipes

Available pipe sizes ranging from 6 mm to 300 mm

Safeguard your compressor from liquid slugging

How to Achieve Better Control and Improve Energy-Efficiency With Vapor Quality Sensors

Are you interested in learning more about how our Vapor Quality Sensors function in liquid overfeed and DX systems? Download our brochure below, where you can find additional information, product specifications, and case studies.

ANZCO FOODS Saves Energy in Their Pumped System with Vapor Quality

Balancing cooling capacity and the lowest possible energy consumption is a challenge in many pumped refrigeration systems. This was also the case for ANZCO Foods.

To alleviate this problem, they installed our Vapor Quality Sensors into their ammonia tunnel freezer system, and despite a complex system design, the sensors were successfully installed.

“The installation of the HB Products vapor quality sensors made the project operate successfully at extremely low temperatures. We are still not sure how this project could have been installed without their use,”

Dennis Carswell, ANZCO FOODS

You can read more about the installation and operational design constraints in the full case study.