Reduce Energy Consumption and Save Money in Your Cold Storage Facility

Defrosting a cold storage facility is important to ensure that the system continues to run efficiently. However, in most facilities the defrost cycles are managed by a timer – and to avoid frost buildup on the evaporator, the interval is set too high, resulting in unnecessary defrosting and a costly energy bill. Discover how to save money by reducing your energy consumption.

Are You Looking to Optimize Your Defrosting Management?

Fill out the form to discover how

Increase Energy Efficiency Without Compromising on Performance

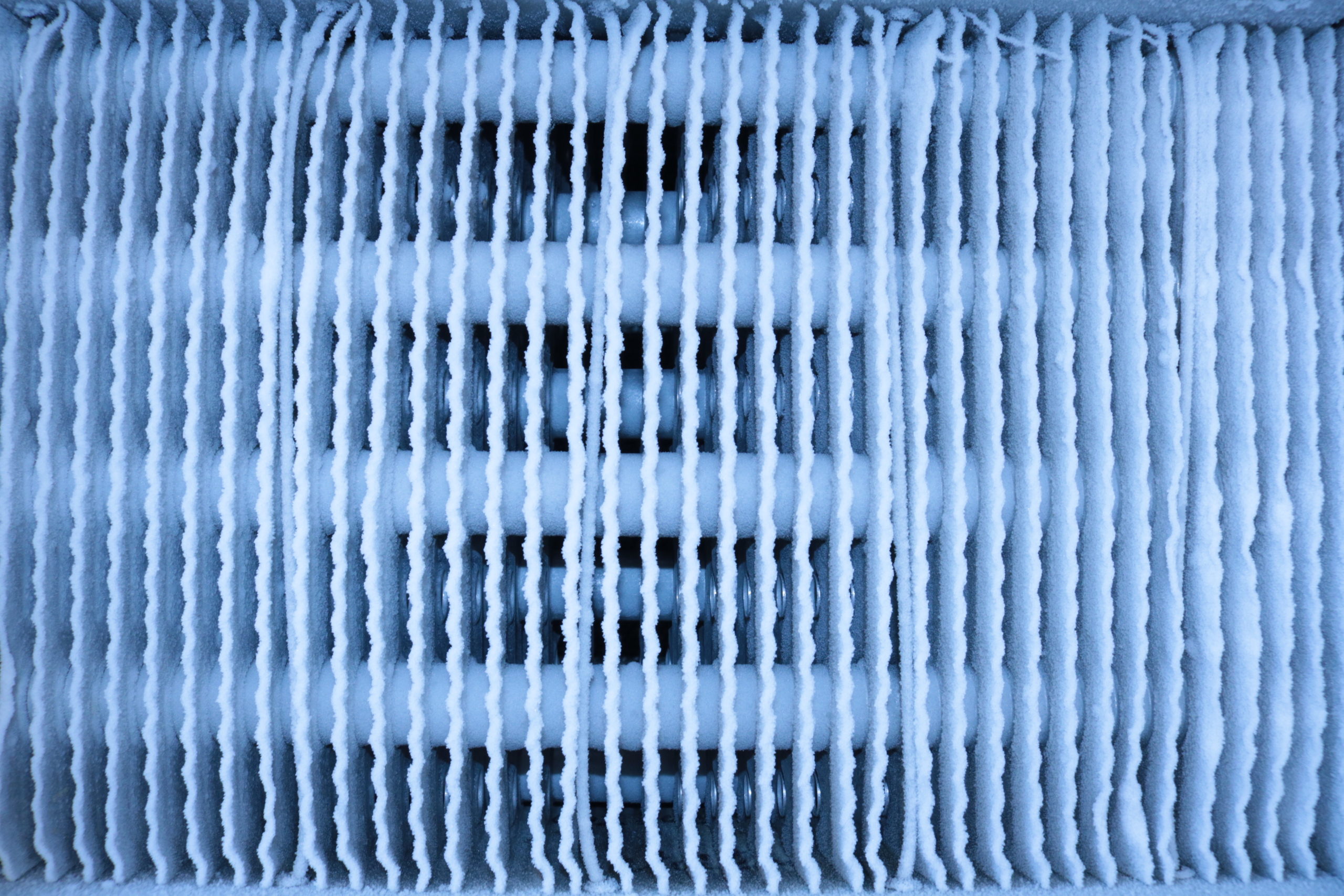

Frost buildup is unavoidable in a cold storage facility, but as the ice thickens the performance of the evaporator decreases.

This makes defrosting an important part of keeping your facility running efficiently.

However, the cost of defrosting can quickly add up – especially because it is usually done at a scheduled interval that is set much too high as a safety precaution.

By installing the Defrost Sensor HBDF on new or existing evaporators, you can eliminate this problem and significantly reduce your energy consumption.

Sensors in existing cold stores have shown a reduction in defrost cycles of 50-70% on a yearly basis in comparison to a traditional timer-based approach.

So, download the paper now and learn more about how to save money by stopping your excessive defrost cycles.

One of HB Products’ customers is Arla Foods, a multinational cooperative dairy, and they are very pleased with the HBDF.

”We have reduced defrost cycles from 7 times per day to just 1, so this has definitely had a positive impact

on electricity consumption.”

Morten Asferg, Engineer Global Facility, Arla Foods, on installation the HBDF Sensor.