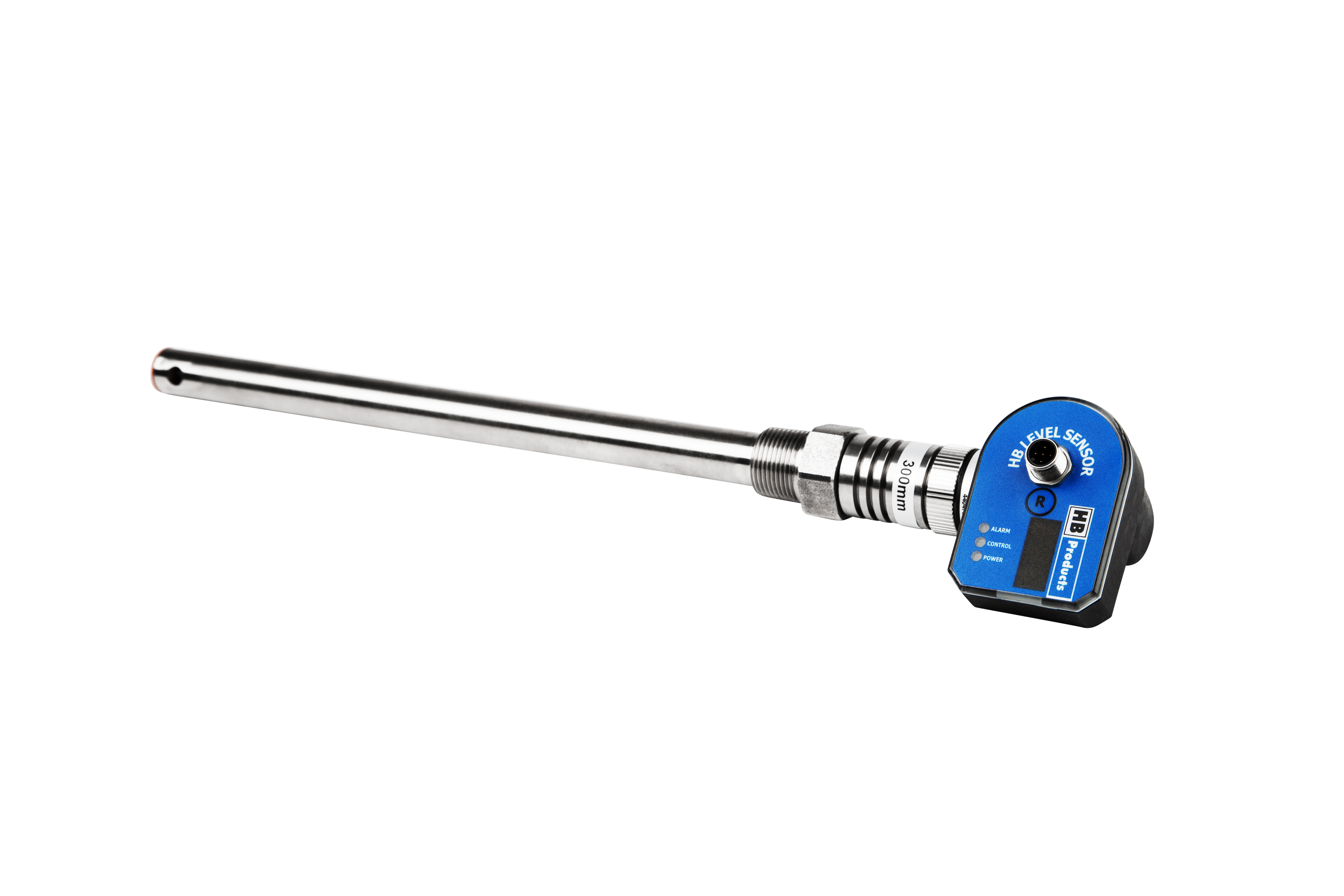

Precise Measurements with Accurate Sensor Technology

HB Products specializes in designing and developing second-to-none sensors for refrigeration and heat pump systems. All our sensors are engineered to withstand harsh environments and extreme temperatures, ensuring accurate and continuous measurements. How do they work? Find out in the animations below.

How Do Our Liquid Level Switches

and Liquid Level Sensors Work?

Ensuring Longevity with a

Practical Split Design

By implementing our Liquid Level Switches, Liquid Level Sensors, or a combination of both, you get essential insights and a dependable solution to effectively monitor and control your refrigeration system.

Our sensors and switches have an efficient split design, making them not only user-friendly for everyday operations but also easy to maintain. This design choice significantly enhances the durability and longevity of our devices.

To ensure the optimal solution, our sensors have been designed to handle all types of liquids.

This means, whether you use natural refrigerants like ammonia, propane, or CO2, or need a sensor for synthetic refrigerants such as HFCs, CFCs, or HFOs, HB Products has a sensor designed to accommodate your requirements.

A Simple and Cost-Effective Approach to Automatic Oil Return

Our oil ejector is propelled by hot gas and used for returning oil from a low position up to the suction line or compressor. It is typically with two solenoid valves, which can be controlled directly by a HBOR/C or HBOC/C making up a simple oil return system.

HBOR/C is used for ammonia systems where you have liquid ammonia or gas on top of the oil. HBOC/C is used for all other systems where you only have gas on top of the oil. Both switches have a direct control output for the valves.

For ammonia systems the oil return can also be controlled from a HBOR or HBSR providing input to a PLC or similar.

The ejector is a cost-efficient and durable solution for oil return, which does not need maintenance.

The ejector works with hot gas up to 130 bar (1885 psi), and it can handle liquid/hot-gas temperatures from -60°C to +150°C (-76°F to 302°F).

The oil pumping capacity depends on the viscosity and potential pressure loss between the ejector and the suction line.

Optimize Your Defrost Cycles with Our Defrost Sensor

By measuring frost accumulation on the surface, our Defrost Sensor initiates defrost cycles only when necessary.

The Defrost Sensor can be installed on both new and existing systems and has been shown to reduce the number of defrost cycles, which typically results in a 20-40% savings in energy costs.

You can see how the Defrost Sensor works in our animation.

Store Ice During Off-Peak Hours with Our Ice Bank Sensor

Our Ice Bank Sensor is designed to optimize ice storage management in industrial and commercial refrigeration systems.

Using the capacitive measuring principle, the sensor accurately monitors ice build-up, enabling efficient ice storage during off-peak hours. This not only reduces energy consumption but also enhances system reliability by preventing excessive ice formation.

Watch the Ice Bank Sensor in action through the animation

LET US INCREASE YOUR UPTIME, SAFETY, AND EFFICIENCY